There are many fasteners types used in the marine industry – from simple nails and screws to more complicated bolts and rivets. Selecting the right fastener for the job is important, as is ensuring that it is properly installed. This guide will provide an overview of the most common marine fasteners, their uses, and tips for proper installation.

The Different Types of Marine Fasteners

There are many different types of marine fasteners, each with its own specific purpose. The common marine fasteners are the different types of screws and nuts, which is used to attach two pieces of material together.

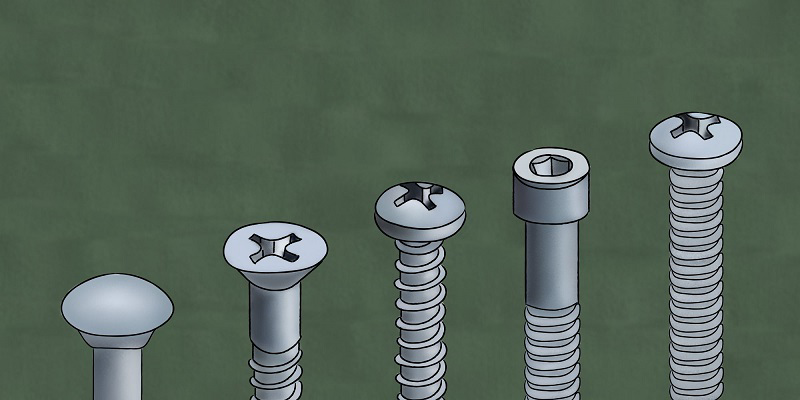

screws

The most common type of screw is the flat head screw, which is used to attach two pieces of material together. These screws have a wide, flat head that is easy to grip and turn. They are also very strong and can be used in a variety of applications.

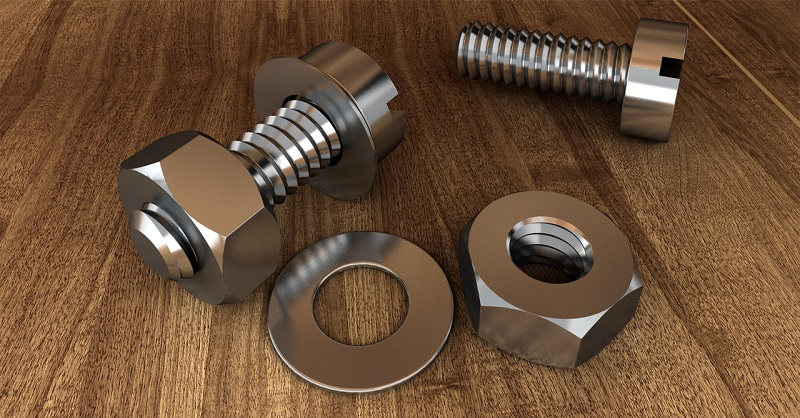

Bolts

Bolts are another type of marine fastener that is used to attach two pieces of material together. Bolts come in a variety of sizes and shapes, depending on their intended use. The most common type of bolt is the hex head bolt, which is used to attach two pieces of material together. These bolts have a hexagonal head that is easy to grip and turn. They are also very strong and can be used in a variety of applications.

Nuts

A nut is a female fastener that is threaded on the inside, while a washer is a flat piece of metal with a hole in the center that is used to distribute load or prevent loosening. Nuts and washers are available in many different sizes and materials, so it’s important to choose the right size and material for your application.

Rivets

Rivets come in a variety of sizes and shapes, depending on their intended use. The most common type of rivet is the pop rivet, which is used to attach two pieces of material together. These rivets have a small, cylindrical head that is easy to grip and turn. They are also very strong and can be used in a variety of applications.

How to Select the Right Marine Fastener for the Job

With so many different types of marine fasteners available on the market, it is important to select the right one for the job at hand. Different fasteners are better suited for different applications, and some are even specifically designed for use in saltwater or high humidity environments. When selecting a marine fastener, it is important to consider the following factors:

- The type of material the fastener will be used with

- The environment the fastener will be used in

- The level of stress the fastener will be subject to

- The desired level of holding power

For example, if you are looking for a marine fastener to use with aluminum, you will want to avoid using a galvanized fastener, as the zinc in the galvanized coating can cause corrosion.

Additionally, you will want to take into account whether the fastener will be used above or below the waterline. If it will be used below the waterline, you will need to select stainless steel or other corrosion-resistant fasteners. Finally, you need to consider the amount of stress the fastener will be under. If it will be subject to high loads, you will need to select a stronger fastener, such as a grade 8 bolt.

Tips for Installing Marine Fasteners Properly

Marine fasteners are used to hold together the hulls of boats and other marine vessels. They must be installed correctly in order to ensure the safety of the vessel and its occupants. Here are some tips for installing marine fasteners properly:

- Use the correct tools. Marine fasteners should only be installed using specialized tools designed for the job. This will ensure that they are installed correctly and will not come loose over time.

- Follow the manufacturer’s instructions. When installing marine fasteners, it is important to follow the instructions provided by the manufacturer. This will ensure that they are installed properly and will not cause any damage to the vessel.

- Inspect the fasteners regularly. Once marine fasteners are installed, it is important to inspect them regularly to make sure that they are still securely in place. This will help to prevent any accidents or damage to the vessel.

By following these tips, you can ensure that your marine fasteners are installed properly and will not cause any damage to your vessel.

Conclusion

There are a variety of marine fasteners available on the market, each with its own unique benefits. When selecting the right fastener for your needs, it is important to consider the specific application and environment in which it will be used. Hope this article can help you choose the right marine fasteners.

Suggested Reads: How to change gears in drift hunters