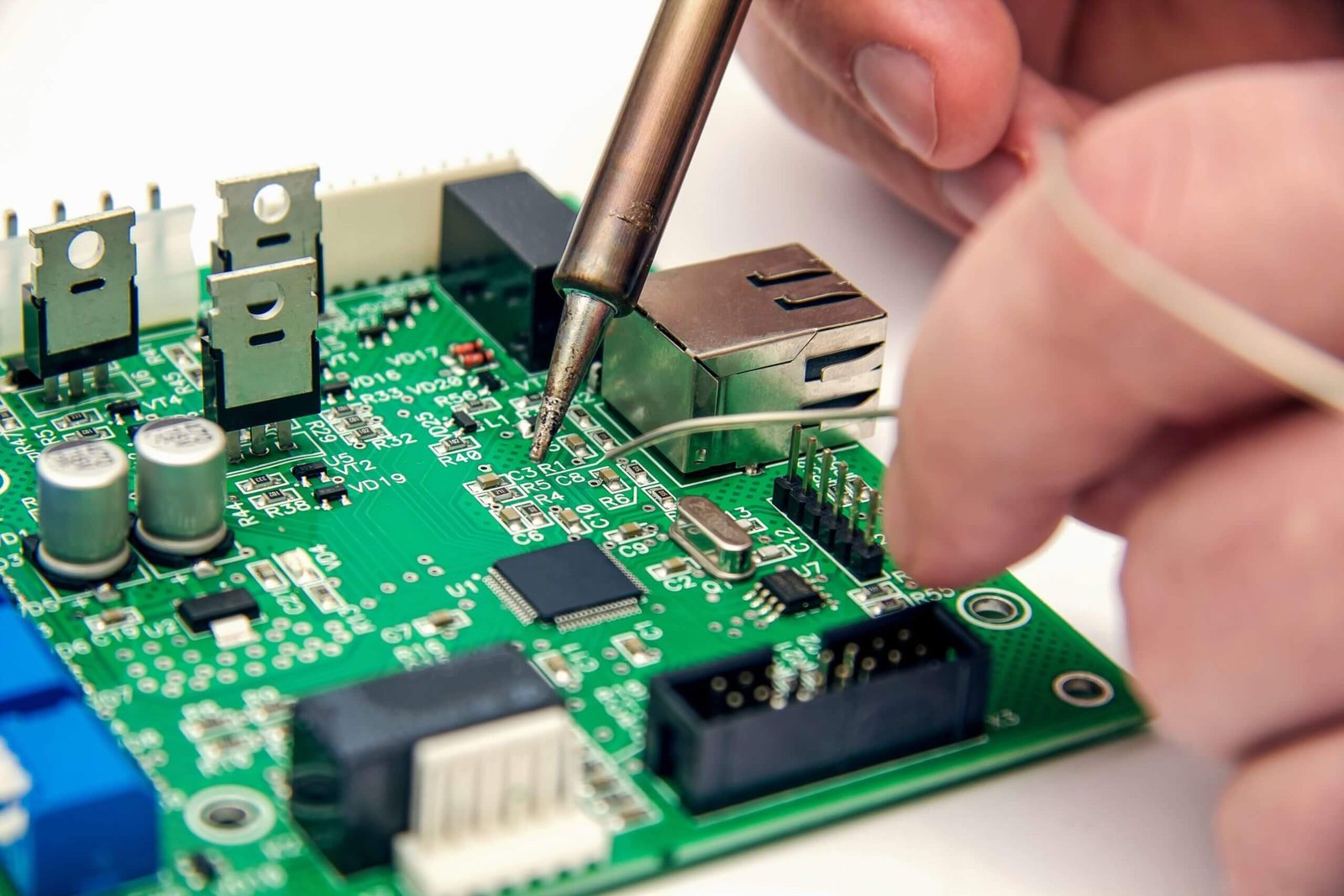

Printed circuit boards (PCBs), also known as printed wiring boards, refer to an electronic circuit, usually made of fiberglass and is composed of thin strips of conductors such as copper that are etched from a layer of insulating sheet. PCB is useful in devices by providing a conductive path for the electronic components. Most electronic devices such as smartphones are dependent on printed circuit boards (PCBs) for their foundation, and without them, these devices will cease to function.

Before a PCB can run, it is vital to ensure that it is functioning as intended. A PCB prototype, which is an early sample, is built for testing and design for its functionality. Engineers will normally go through the design from top to bottom and testing will begin with the visual model towards the functionality of the prototype.

Here are 3 reasons why prototype PCBs are the best way to get a start:

1) Prototypes PCBs Reduce Completion Timelines

To create a final printed circuit board, engineers usually go through several itinerary processes. These usually serve important functions in the production stages, such as allowing engineering teams to test the product at various manufacturing stages before it is finally ready; this means the product manufacturing process is shortened as follows:

Complete Testing of the Printed Circuit Board

PCB prototypes allow for proper testing, and as such, problems identified are quickly corrected at each stage; this means that by the time the product is complete, thorough scrutiny would have been applied in identifying and correcting errors. Without this process, rectifying mistakes would take a considerable length of time, hence leading to happy customers

2) Prototype PCBs Allow for Individual Testing of Components

Although engineers use prototype PCBs for testing, it is more beneficial to test each component and function. The singular tests are finally incorporated into the entire PCB, hence ensuring synchronized working. Testing individual components is useful in the proof of concept whereby engineers identify whether the board is working or not and areas to rectify. Testing also allows to break down complex designs into basic parts that form the PCBs.

3) Prototype PCBs Help in Cost Reduction

The production of a standard PCB is costly, and any chance for errors means additional costs. Prototype PCBs may help engineers cut down on these costs by determining and pinpointing cost-saving adjustments. The sooner the production team catches a flaw, the sooner it can be fixed, hence less cost and time in rectifying it. On the other hand, a later problem after completion of production means the whole PCB might need disassembly, resulting in more costs.

PCB prototyping is a powerful tool for engineers and designers in the design and testing process of PCBs, ensuring the final product is of top quality. Prototype printed circuit boards are essential due to benefits such as reduced production times and lowered costs, among others